SMAR LD300 Series

Pressure, Level and Flow TransmittersTypes of Transmitters

Differential Transmitter – LD300D and LD300H

Differential pressure measurement is achieved by applying pressure to the high and low sides of the transmitter. The LD300H models are designed for work with high static pressures.

Flow – LD300D and LD300H

The differential pressure is generated by a primary flow element and the flow measurement is obtained by the square root function.

Absolute Pressure – LD300A

Absolute pressure is applied on the high side of the transmitter and on the low side there is a vacuum chamber, which is the absolute zero reference for the capacitive cell.

Gauge Pressure – LD300M

Gauge pressure measurement is obtained by applying pressure to the high side of the transmitter and the low side is open to the atmosphere, thus providing a local atmospheric pressure reference.

Level – LD300L

The transmitter allows a direct flanged connection to vessels and tanks. It is also available with an extension.

Characteristics

- Accuracy of ± 0.04%;

- Stability of ± 0.15% of the URL – 12 Year Warranty;

- Rangeability of 120:1;

- span min. from 50 Pa (0.2 inH2O) to a range limit of 0 to 40 MPa (0 to 5800 psi);

- Static pressure up to 320 bar;

- Direct digital capacitance measurement;

- Non-interactive zero and span;

- Local adjustment of zero and span;

- Remote parameterization and calibration;

- Output functions: linear, V x, V x3 and V x5 ;

- Linearization for tank;

- Alphanumeric digital indication;

- Light and compact;

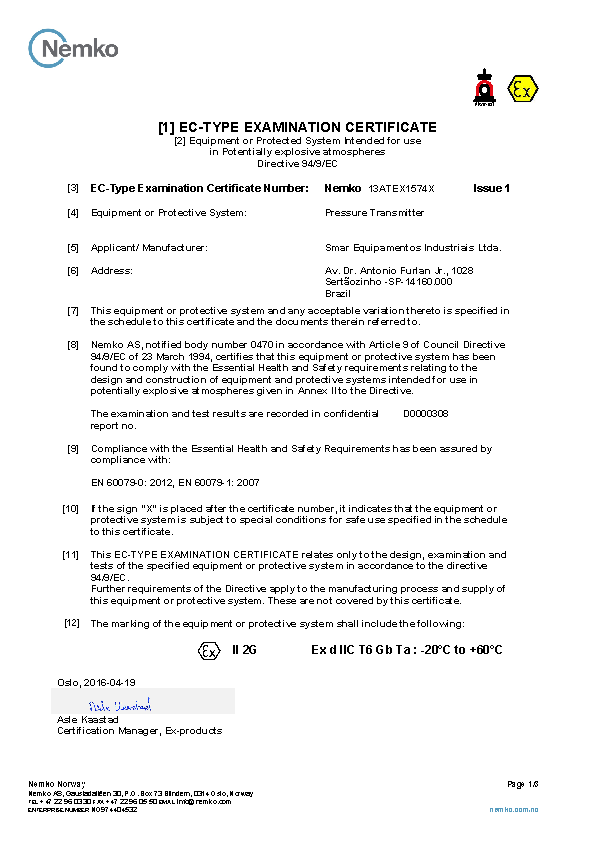

- Explosion and weather proof housing (IP67);

- Intrinsically safe;

- Signal simulation for loop testing;

- Persistent totalization;

- User configurable unit;

- Configurable local adjustment;

- Electromagnetic compatibility according to IEC 61000-6-2:1999, IEC 61000-6-4:1997

- and IEC 61326:2002;

- Password configuration protection;

- Three technology options: HART Revision 7, FOUNDATION fieldbusTM and PROFIBUS PA.

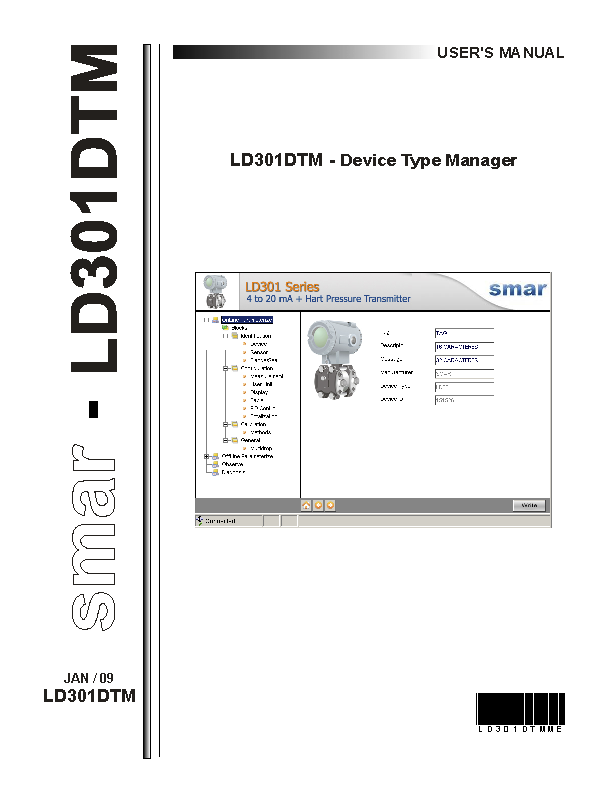

HART Revision 7 – 4 to 20 mA – Model LD301

- Output current updated at 100 ms with 0.075 ?A/bit resolution;

- Improved performance due to dedicated math co-processor;

- Multidrop operating mode;

- PID control function;

- Supports DTM and EDDL;

- Flow measurement;

- FMEDA and MTBF analysis of 244 years.

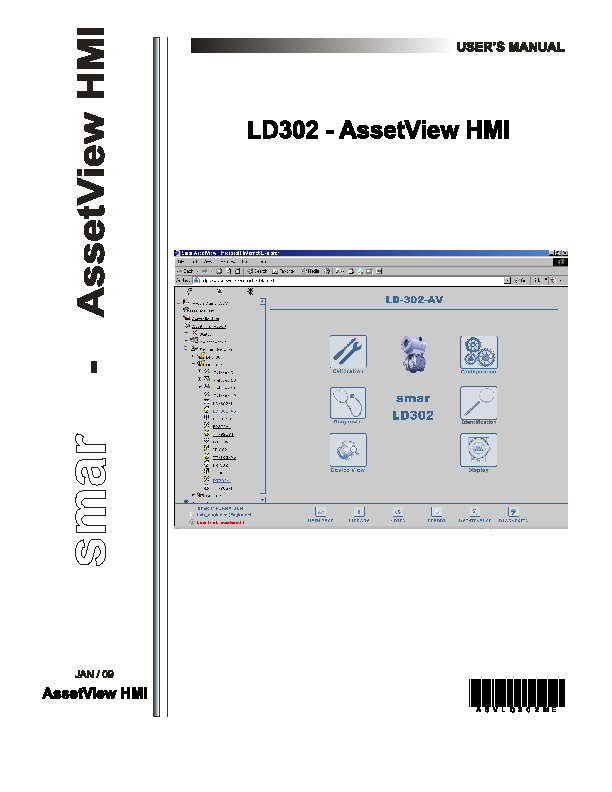

FoundationTM Fieldbus – Model LD302

- 17 different types of function blocks for advanced diagnostics and control strategies;

- Instantiation of up to 20 function blocks;

- Execution of up to 29 external links;

- 12 mA consumption current;

- Dynamic instantiation of blocks;

- FOUNDATION fieldbusTM registered and ITK approved;

- Enabled by MVC (Multivariable Container);

- 186 year old MTBF.

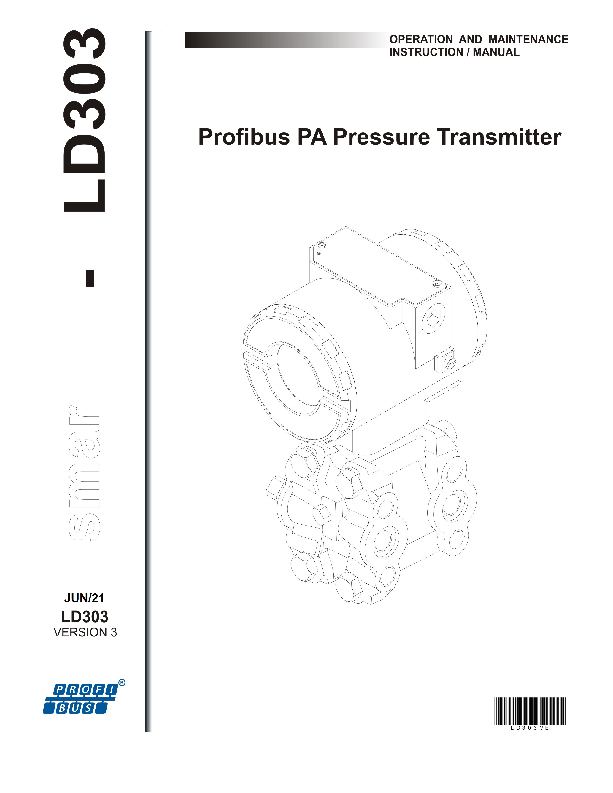

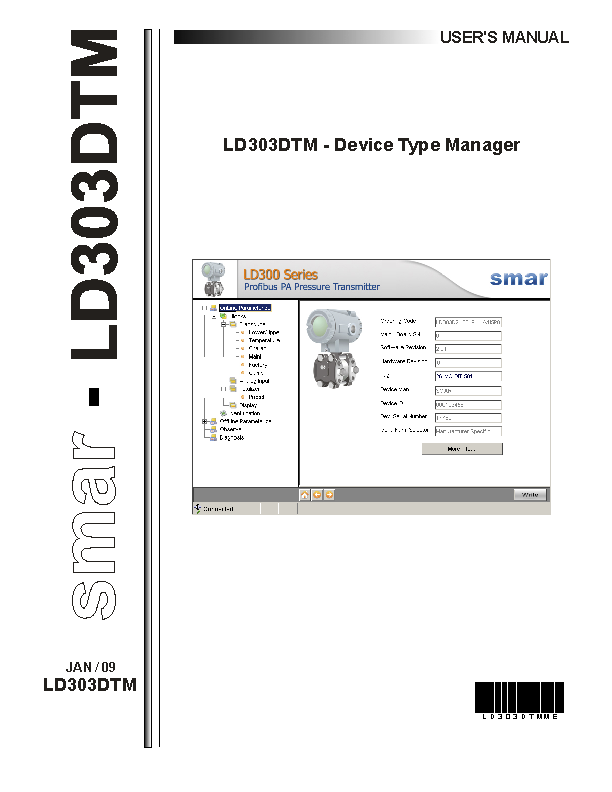

Profibus PA – Model LD303

- 12mA consumption current;

- Function blocks for analog inputs and totalization;

- Integration with SMAR Profibus View and Simatic PDM

- Supports DTM and EDDL;

- Profile 3.0 facilitates interchangeability;

- MTBF of 186 years.

Applications with Remote Seal

The SR301 is a remote seal designed for chemical and thermal isolation of the capacitive cell. The LD300 series can be mounted with seals on either one or both sides of the sensor. SR301 options include: “T” flange, flush connection, threaded, sanitary and extension flanged. The flush connection allows cleaning of the diaphragm to remove deposits without disconnecting the seal and also allows to purge gases from the pressure tap.

Typical applications for the LD300 series with remote seal:

- Corrosive process fluids;

- Process fluids with suspended or viscous solids;

- Process fluids that can freeze or solidify;

- Process temperatures higher than those supported by the transmitters;

- Replacement of impulse lines and condensed legs;

- Bubbling system.

See the SR301 Series Catalog for more information on applications and specifications.

Applications with Sanitary Transmitters

The LD300S series is specially designed for food and other applications where sanitary connections are required. Tri-clamp and threaded connections allow for quick and easy maintenance. Tri-clamp and other connections follow the 3A (74-02) standard for food applications. For more information, see SMAR’s SR301 Series catalogue.