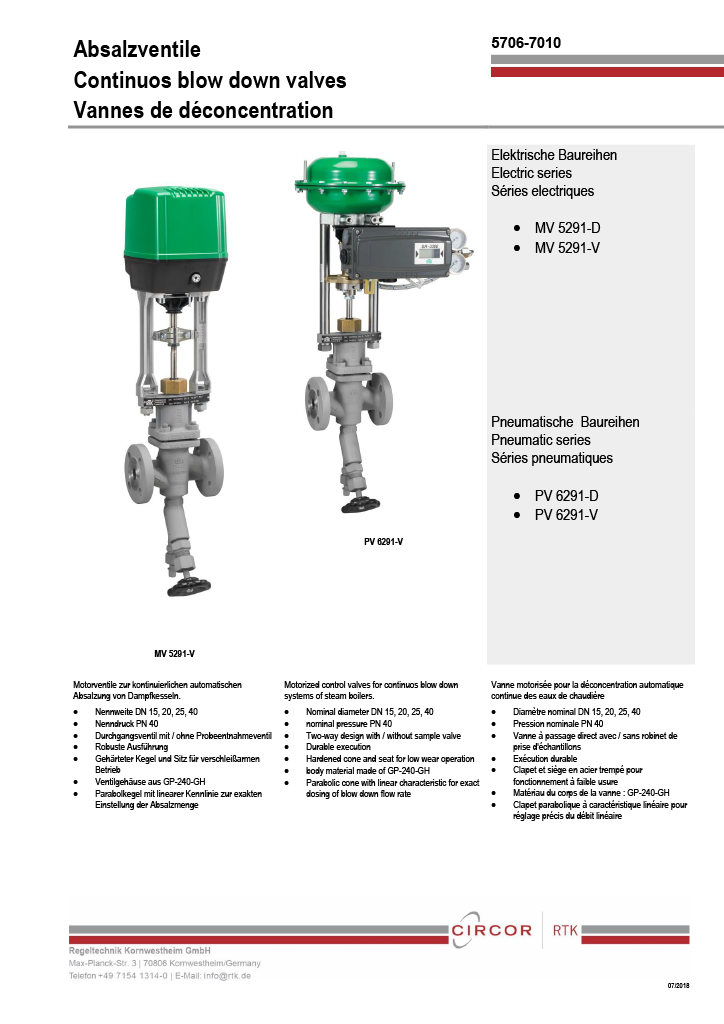

RTK MV 5291 V-D / PV 6291 V-D

Electric or pneumatic actuated continuous blowdown control valve for steam boilersContinual evaporation during steam generation increases the dissolved solids content in the boiler water. To keep this content within the limits and in accordance with regulations is important to blow out the boiler water continuosly or with intervals.

RTK MV (electric) 5291 V-D, PV (pneumatic) 6291 V-D are actuated control valves created for steam boiler continuous blow down for excact dosing of blow down flow rate. The dimension of the continious blow down valve is on normal operation 5% of the boiler steam rating. The maximum blow rate (full valve opening) is sized for 10% steam flow.

Meanings V or D are accordingly with or without sampling valve.

For more precise sizing contact our support.

Electric or pneumatic actuated continuous blowdown control valve for steam boilers | Two-way design with or without sampling valve

DN 15, 20, 25, 40

PN 40

Carbon Steel

Media temperature: up to 530°C

Class IV

Flange, Butt weld by request

Parabolic cone with linear characteristic, Hardened cone, Stellited seat

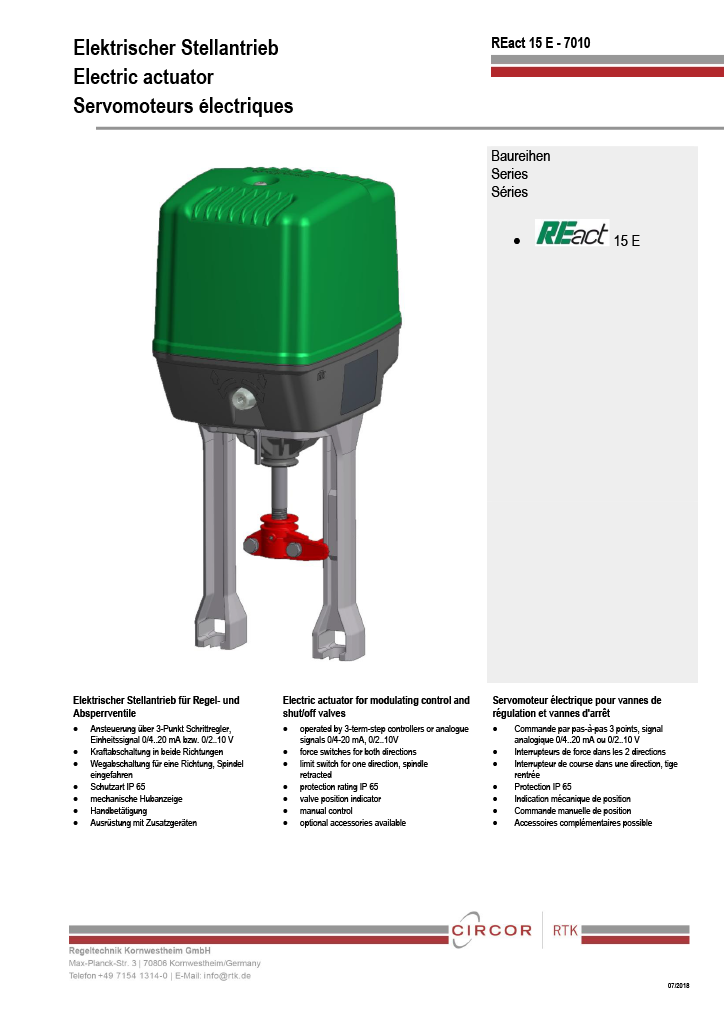

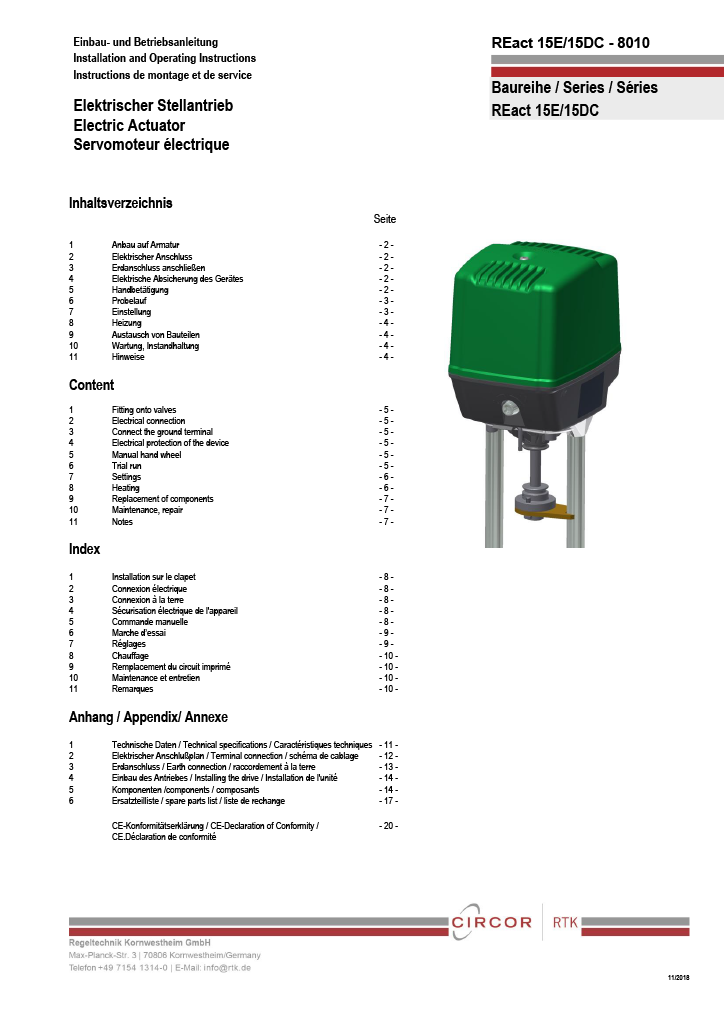

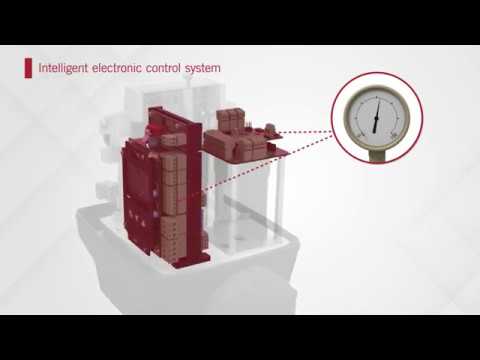

Electric actuated MV serie

3 step control, I/O 0/4-20mA, 0/2-10V, Profibus DP, additional limit switches

Supply voltage: 24 / 115 / 230 VAC, 24 VDC

Pneumatic actuated PV serie

electro-pneumatic positioner, I/O 4-20mA, Profibus DP, 3/2 solenoid valve, limit switches, alarm module, pressure gauges, air filter regulator

RTK

Germany

Biotechnology, Chemical, Boiler and Power Plants, CHP, Breweries, Building materials, Dairies, Distilleries, Food and Beverage, Hospitals, Mining, Metallurgy, Oil&Gas, Refineries, Pharma and cosmetics, Pulp&Paper, Textile, Laundries, Timber, Pelletizing, Tire, rubber and plastic, Water and wastewater

Condensate, Superheated water, Steam, Superheated steam, Water and Wastewater