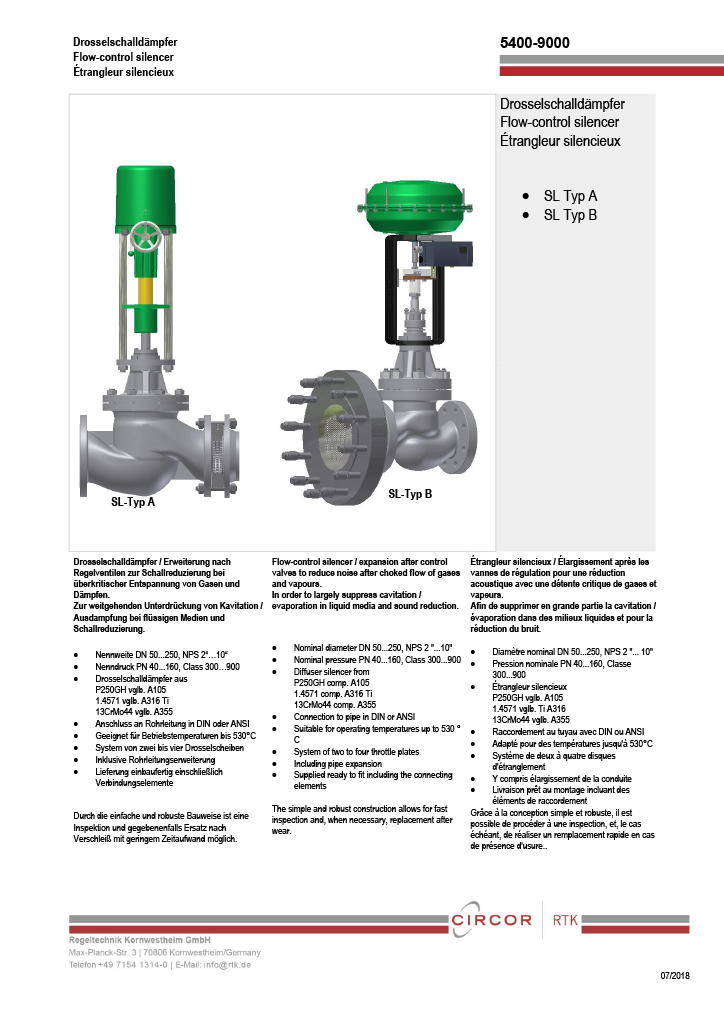

RTK SL Typ A-B Silencer

Flow-control silencer for gases and vapoursFlow-control silencer / expansion after control valves to reduce noise after choked flow of gases and vapours. In order to largely suppress cavitation / evaporation in liquid media and sound reduction.

With the help of a diffuser silencer as a fixed flow resistor an increase of the dynamic pressure results after the valve. Through the single / multi step pressure reduction to the required after-pressure a significant reduction of sound pressure level is gained.

The noise reduction can be up to 25 dB (A), depending on the differential pressure ratio, the formation of the throttle plates and the throttle body of the valve, when compared to a one-step expansion.

SL-type A for liquid media

Separate housing with two or three throttle plates, which is clamped between the valve and piping.

SL-type B for gases and vapours

Diffuser silencer with two to four throttle discs in a separate casing including pipe expansion.

Flow control diffuser silencer including pipe expansion

For valve sizes: DN 50-250 (2″ – 10″)

DIN PN 40-160 / ANSI 300-900

Cast Steel, Stainless Steel, Creep Resistant Cast Steel, other materials by request

Media temperature: up to 530°C

Class IV, IV-S1

For flanges EN 1092 form B1 or ASME 16.1, other by request

RTK

Germany

Biotechnology, Chemical, Boiler and Power Plants, CHP, Breweries, Building materials, Dairies, Food and Beverage, Mining, Metallurgy, Oil&Gas, Refineries, Pharma and cosmetics, Pulp&Paper, Timber, Pelletizing, Tire, rubber and plastic

Air, Gas, LPG, Vapours, Exhaust gases, Neutral and Agressive Liquids, Steam, Superheated steam