SMAR LD293

PROFIBUS Pressure TransmitterThe LD293 – PROFIBUS Pressure Transmitter is from the first generation of PROFIBUS-PA devices. It is an economical alternative gage pressure transmitter. It is based on a field-proven capacitive sensor that provides reliable operation and high performance.

This lightweight design eliminates the need of mounting brackets and transmitter support in many applications. Its microprocessor-based electronics allow for total interchangeability with SMAR capacitive sensors, correcting automatically sensor characteristic changes caused by temperature fluctuation.

The digital technology used in the LD293 – PROFIBUS Pressure Transmitter enables the choice of several types of transfer functions, an easy interface between the field, the control room and several interesting features that considerably reduce the installation, operation and maintenance costs.

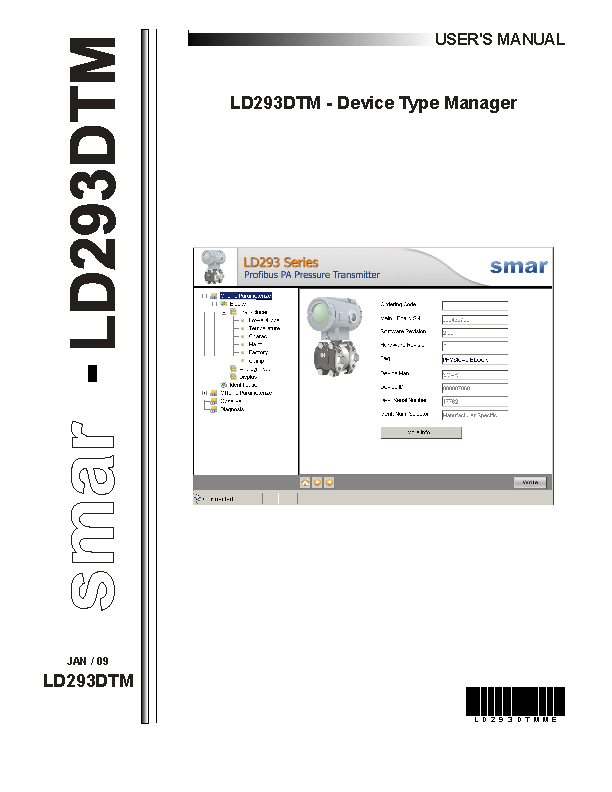

Parameterization and Diagnostics

LD293 – PROFIBUS Pressure Transmitter can be configured using SMAR PROFIBUS View and Simatic PDM and by the FDT (Field Device Tool) and DTM (Device Type Manager) concept tools, such as FieldCare™ and PACTware™. It can also be integrated by any PROFIBUS System using the GSD file.

PROFIBUS PA also has quality and diagnostic information, improving plant management and maintenance. The EDDL and DTM are available in SMAR website. Conforms to profile 3.0.