Complete Steam Plants

Fully equipped steam container unit is our solution in case isolation from the rest of your plant is required. It contains all components necessary to operate an entire plant.

After connecting the main service and commissioning, steam is at your disposal in less than 5 minutes. The self contained unit is flexible, allowing permanent, as well temporary positioning.

On inquiry we can take over full or partial installation of the steam system. If you choose to contract out to other companies, we can carry out consultation and supervision for your containerized unit.

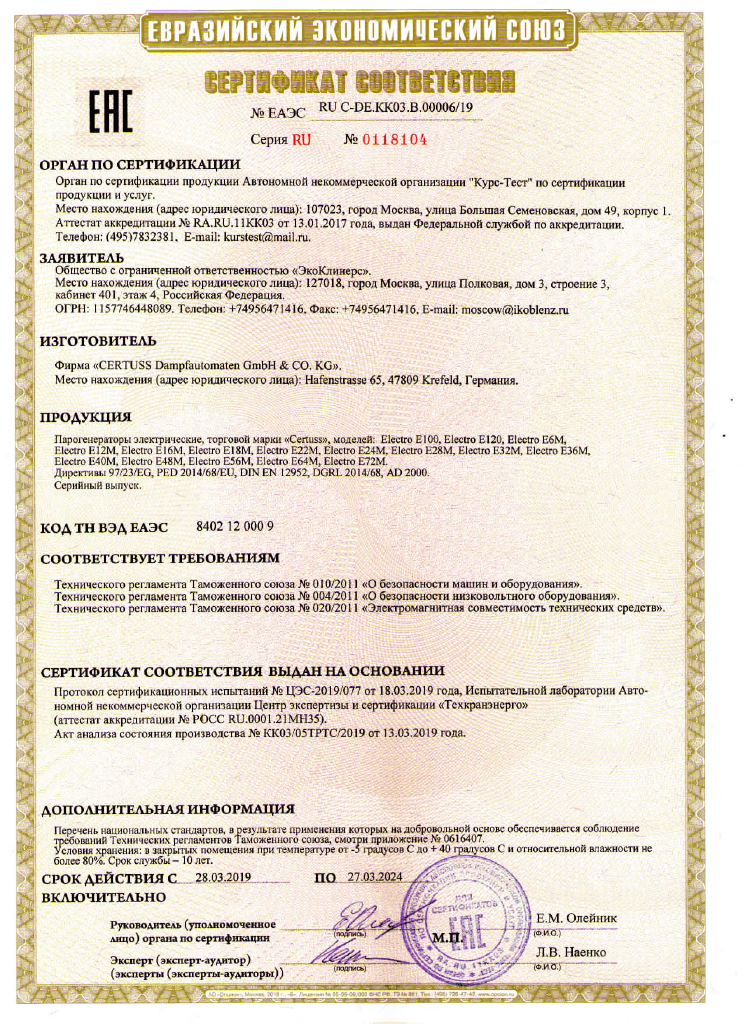

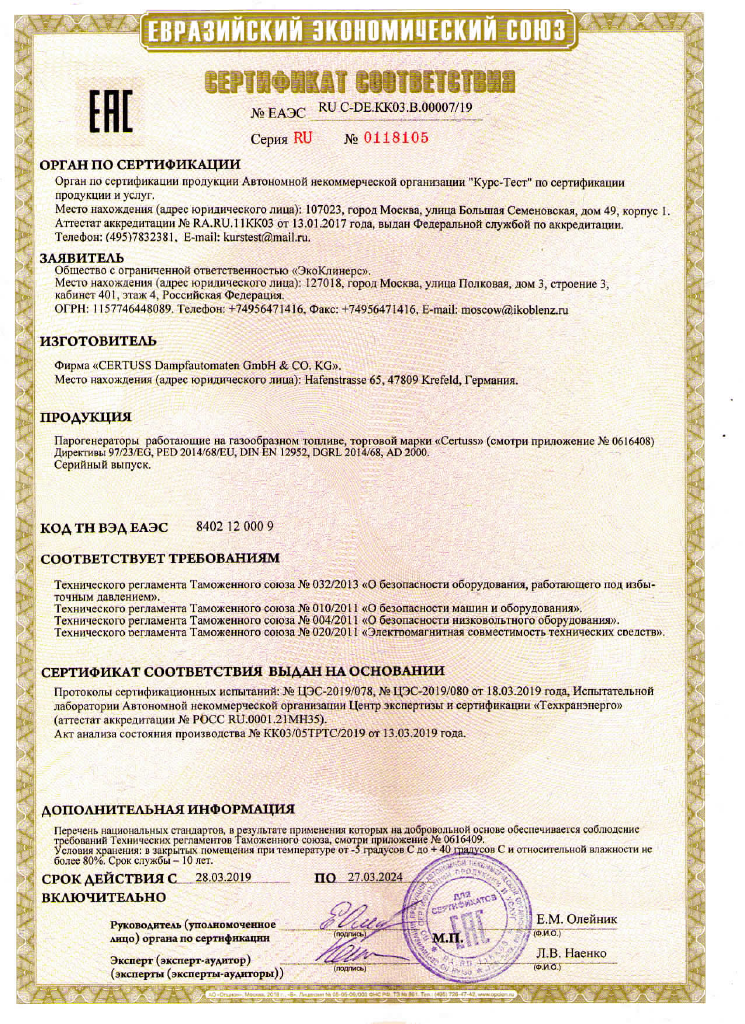

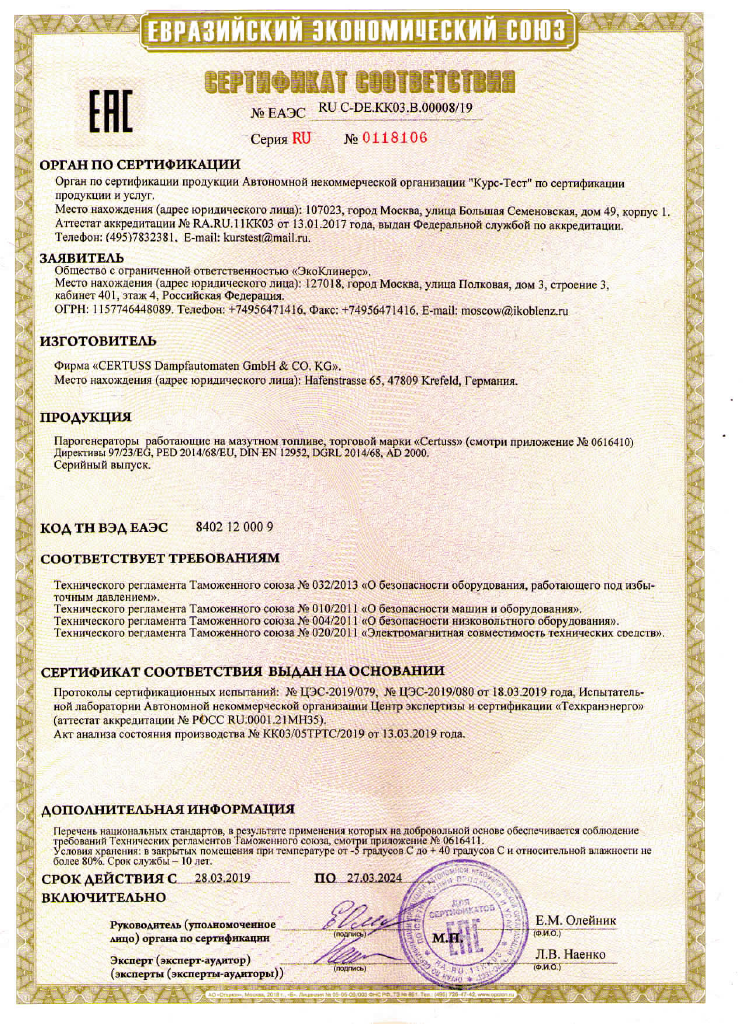

All advantages at a glance

- Up to 98% thermal efficiency

- Fully automated, unmanned operation available

- Silent operation, less than 75 dBa sound pressure

- BMS compatibility with Profibus/CANbus, Profinet, Modbus, BACnet etc

- Remote access via Ethernet, Wi-Fi or GSM (Cellular)

- Remote maintenance and control possible with iPad or iPhone

- Predictive maintenance: informing of potential issues before they occur

- Minimal and easy maintenance with spare parts available up to 20 years

- 24/7/365 aftersales support

- Less pollution through low water drainage

- Available steam production up to 20 t/hour

- Operation pressure up to 18 barg

- Also available for clean steam or steam sterilisation

CERTUSS

Germany

Biotechnology, Chemical, Boiler and Power Plants, CHP, Breweries, Building materials, Dairies, Distilleries, Food and Beverage, Hospitals, Mining, Metallurgy, Oil&Gas, Refineries, Pharma and cosmetics, Pulp&Paper, Textile, Laundries, Timber, Pelletizing, Tire, rubber and plastic, Water and wastewater

Steam, Superheated steam